The need for high-grade recycled RPET flakes has increased significantly among global brands that are looking to meet their ESG goals. The use of recycled PET as raw material for food grade applications or for micro denier filament application has been on the rise. This increase in demand shows that there is a growing interest in using recycled PET bottles as a sustainable packaging solution. In order to meet these changing demands and to ensure the highest quality of recycled PET flake, one of the most important factors is to optimise the recycling process and equipment of PET bottles. The right choice of PET bottle recycling process is the right choice of grantee to support the recycling of waste PET into rPET flakes.

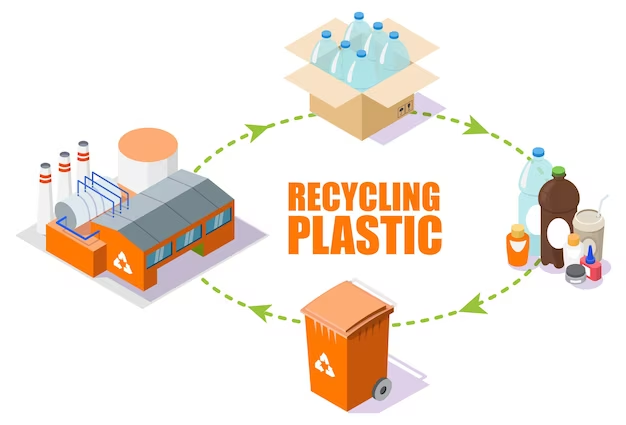

Let’s take a closer look at the complex process of recycling PET bottles and how it plays an important role in protecting the environment.

Process of PET Bottle Recycling

- Collection

The journey of PET bottle recycling begins with collection. Empty bottles are collected from various sources, including households, commercial establishments, and recycling centers. Efficient collection systems ensure that a substantial amount of used PET bottles are gathered, preventing them from ending up in landfills or polluting natural habitats.

2. Sorting

Once collected, the next step is sorting. PET bottles are sorted based on color and type to ensure homogeneity in the recycling process. This step involves separating clear bottles from colored ones and removing any contaminants like caps, labels, or other non-PET materials. Advanced sorting technologies such as infrared sensors and automated systems streamline this process, enhancing efficiency and accuracy.

3. Cleaning

After sorting, the PET bottles undergo thorough cleaning to remove any remaining residues or impurities. This cleaning process typically involves washing the bottles with hot water and detergent, followed by rinsing to ensure they are free from any contaminants. Clean PET bottles are essential for producing high-quality recycled materials.

4. Shredding

Once cleaned, the PET bottles are shredded into small flakes using specialized equipment. Shredding breaks down the bottles into manageable pieces, increasing their surface area and facilitating the subsequent processing steps. The size of the flakes may vary depending on the intended application of the recycled PET material.

5. Methods and Pelletizing

The shredded PET flakes are then melted and pelletized to form uniform granules or pellets. This process involves heating the flakes to a specific temperature until they melt into a viscous liquid. The molten PET is then extruded through a die and cooled to solidify into pellets. These pellets serve as the raw material for manufacturing various products, including new bottles, textiles, and packaging materials.

6. Reprocessing

The recycled PET pellets undergo further processing to meet the desired specifications for different applications. This may involve additional purification steps to remove any remaining impurities and improve the quality of the recycled material. Advanced technologies such as solid-state polymerization may also be employed to enhance the properties of the recycled PET, making it suitable for a wide range of end uses.

7. Manufacturing

The final step in the PET bottle recycling process is manufacturing new products using the recycled PET pellets. These pellets can be used to produce a variety of items, including bottles, containers, fibres for textiles, and even automotive parts. By incorporating recycled PET into the manufacturing process, companies reduce their reliance on virgin plastic and minimize the environmental impact of their operations.

Conclusion:

The process of PET bottle recycling represents a remarkable journey of transformation, where used plastic is given new life and contributes to a more sustainable future. From collection to manufacturing, each step in the recycling process plays a crucial role in conserving resources, reducing waste, and mitigating environmental pollution. By embracing PET bottle recycling, we can take significant strides towards building a circular economy where materials are reused, repurposed, and recycled to create a greener and more prosperous world.